VACOMASS® econtrol

- Permanent monitoring of the opening degree of all control valves in the system

- Calculates required header pressure and transfers the data to the local PLC or SPC

- Reduces operation costs in low-load phases without any loss in operation safety in air supply and distribution

The VACOMASS® control module is an electronic module, which calculates actual required header pressure setpoint depending on actual air requirements. This pressure is transferred to the local blower management or PLC. The operation can be changed from a constant header pressure setpoint system to a system using a load-depending and adjustable header pressure setpoint.

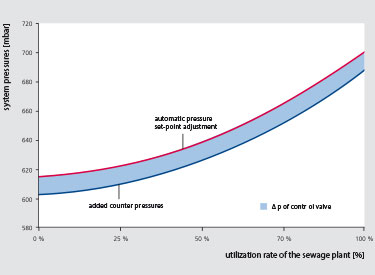

In the case of operating a plant under partial load conditions, the flow-dependent counter pressures will decrease. At constant blower pressure, this is compensated by closing the control valve which results in an increased differential pressure. Instead of throttling the air supply via the valve, however, it makes more sense to provide a variable adjustment of the blower pressure according to the actual air demand. All valves are operated as much open as possible.

For this, VACOMASS® control monitors the operating state of all VACOMASS® systems in order to determine the pressure necessary just to maintain sufficient air supply for the whole installation. This required header is transferred to the PLC or blower management system.

A lower pressure level, however, results in less energy consumption for the air supply thus ensuring an economical plant operation.