VACOMASS® flexcontrol

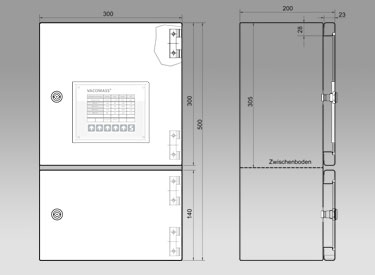

- Modular SPC-based universal control electronics with a graphic display in a field housing with flexible customized configuration

- Thus a control can be realized locally starting with a simple fixed air flow to a load-depending control loop

- For indoor and outdoor installation

VACOMASS® flex control is an SPC-based modular hardware with graphic display and field housing, which can calculate and control the actual required airflow of various tanks and/or aeration zones. All available functions of VACOMASS® electronic modules basic, slave and master are also available on the PSC, adapted to local situations with individual menus on the display.

In the case of a compact VACOMASS® system, the thermal sensor is positioned directly upstream of the control valve. Thus the flow profile will fluctuate steadily during system operation. Without correction, this will lead to errors when measuring the air supply. In order to correct for these flow profile distortions, the setting of the control valve is indicated at any time. To solve this request the control characteristic curve of the valves and specific process data of the sewage plant are stored on the SPC.

The Customer´s PLC in most cases defines and transmits the setpoint for DO-concentration only. In case of control deviations, the new setting of the control valve is calculated, thus allowing for precise adjustment in only one single control step. So switching frequency and finally wear of the gear and valve can be reduced. If the flow meter signal is not reasonable, an approximate value of airflow will be calculated.

Further process parameters like ammonia and/or nitrate concentration can be used and integrated into the control circuit. Any disruption, such as at the aerators and probes, can be detected immediately. Only signals from well-working probes will be considered for control purposes.

VACOMASS® provides comprehensive monitoring functions allowing each process disruption to be indicated immediately. Additionally, the control of the air supply can always be taken over via the process control system. Upon the occurrence of a fault, the control valve will automatically move into a safe position. In this way, VACOMASS® ensures a surplus of oxygen at any time.

The VACOMASS® master module is an electronic module for permanent and automatic calculation of the actual required airflow and the new position of the control valve for local control of air supply. It realizes the adjustment of the valve too.

Data transfer to the PLC or customer´s SPC can be done easily using different kinds of standards: e.g. Profibus DP, Modbus RTU, Ethernet Modbus TCP, Analog signals 4-20 mA and further are available.