Gas Analyzer Station COMBIMASS® GA-s

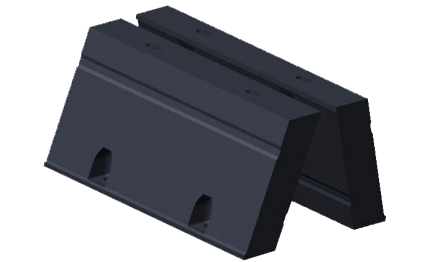

“2-in-1”-Solution Dockingstation

[columns ] [column size="1/2"]- Wall housing cabinet with display module for the indoor-installation in a safe area, admission for the analyzer, hard- and software for measuring function, flushing of the cells after the measurement, power supply of the analyzer

- Automatic bolting device of the gas channels, if the analyzer were taken out

- Gas analysis at two sampling points, four analog input for two flow meter as well as two temperature measurements

- Automatic compensation of the gas flow measurement by actual biogas composition (if integrated)

- Powerful sample pump and encapsulated solenoid valves warrant a continuous operation for years

- Multilingual menu guidance: Operation through touch screen or using 6 [/column]

[/column]

[/columns]

[/column]

[/columns]

Modern biogas fermentation plants cannot meet commercial and environmental requirements without appropriate measuring and analysis technique. For the economical operation of the fermentation plant it is likewise necessary to consider the gas composition and quantity of the individual digester stages. Therefore usually a biogas flow measurement is installed in the generator container. Errors by varying gas pressure, gas temperature and gas composition are not compensated in most cases. Our biogas flow meter use the thermal principle and work also under most difficult conditions reliably, exactly and almost maintenance-free. The flow is determined directly as the standard flow rate, pressure and temperature compensation is not necessary.

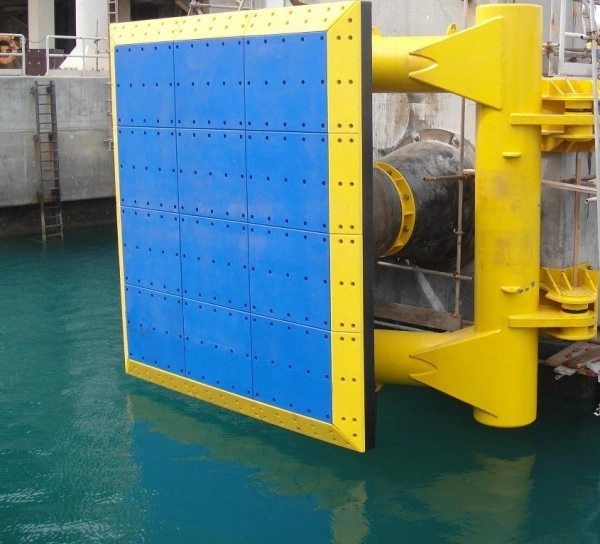

Gas analysis stations require a high technical expenditure, which settles in the long run also in the purchase price and in maintenance costs, to achieve long-term accuracy and reliability. If several gas analysis stations are used, not only the acquisition and maintenance costs will add up, but also measurement uncertainties, so that a trend is promptly recognizable hardly. If an analysis station must be returned for maintenance no current data during this time will be available for the control of the process and recognize trends of gas composition. While using Binder´s portable analyzer in the COMBIMASS® GA-s Docking station, a spare unit can be supplied by Binder during maintenance and repair times.

While the gas composition (except during on and driving off phase) in liquid fermentation plants changes usually only very slowly over the day, the gas flow is subject to certain short term fluctuations, as they are caused for example by the agitator or different humidity content under variations in temperature. Therefore it is appropriate that at each digester a thermal mass flow meter is installed firmly and connected with the Docking station.

While the gas composition (except during on and driving off phase) in liquid fermentation plants changes usually only very slowly over the day, the gas flow is subject to certain short term fluctuations, as they are caused for example by the agitator or different humidity content under variations in temperature. Therefore it is appropriate that at each digester a thermal mass flow meter is installed firmly and connected with the Docking station.

Regarding gas quality a current measurement per hour is completely sufficient. The individual measuring points at the digester can be connected using thin hoses with the Docking station, internal single solenoid valves switch between the measuring points and the PC in the station successively evaluates data. With our Docking Station COMBIMASS® GA-s an almost unlimited number of sample points can be analysed automatically.

In dry bed fermentation stages the measuring cycle must be if necessary adapted. Here not only the gas flow but also the gas composition change substantially more strongly. The methane concentration can from 15 to 70 Vol.-% vary. A combination of the measurement of volume with the gas analysis is inevitable, if the values are to exhibit an acceptable accuracy.

It presents itself in addition at landfills, to measure only at the generator the gas quality automatically and far distant sampling points/ boreholes at the different fields portable. For this the mobile analyzer can be taken out from the station, which keep running measurements of flow and corrected with the last gas analysis values. A low-priced alternative represents the analyzer GA-e, which cannot be used contrary to the GA-m for portable measurements (without losing the advantage of the spare equipment during maintenance/ repair). The GA-e analyzes the methane content on IR basis only and computes the CO2-part. Electro-chemical cells for oxygen and H2S are available also for the GA-e unit.

Special Features Docking station COMBIMASS® GA-s

- Analysis station expansion for up to 13 gas measuring points

- Accuracy of the analysis can be controlled with test gas by an additional gas measuring point automatically and held analysis accuracy

- Feedback of the analysis gas into the process possible

- Analog signals for further flow meter or temperature measurements can be read and evaluated

- Automatic compensation of the humidity with the help of a temperature or dewpoint transmitter

- Efficient measuring data protection and communication using Ethernet Modbus TCP, Modbus RTU using RS485, Analog signals 4-20 mA or professional bus DP as options available

- Data storage on USB-stick possible as an option

- Definition of limit values possible, which release individual alarms or a common alarm using potential-free relays

- Implementation of LEL-room control possible

- Changes of configuration at the measuring program using a code switch possible

- Installation of a climatized cabinet for outdoor installation

- Supply of components or modules for gas preparation (gas cooler, coalescence filter, flaming barrier,