INSTRUM® Blanketing and Inerting

INSTRUM® is working successfully world-wide for more than 30 years in the development, construction and manufacturing of pressure regulators for tank blanketing and inerting. INSTRUM® pressure regulators can be generally used in liquids and gases, particularly in corrosion-proof applications.

[columns] [column size="1/2"]- In most cases, atmospheric operational conditions

- Big membranes typicall

- Corrosion-proof materials are often used

- Combination of regulator and back pressure regulator

- Operation without auxiliary power

- Very safe operation[/column]

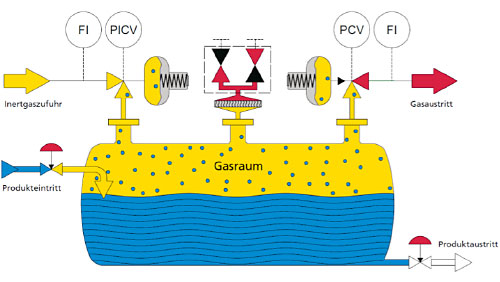

THE SYSTEM

Tanks and containers, like single tanks, large tanks, pre-, intermediate, final product, agitated and reaction vessels, different kinds of the centrifuges and decanters and many further process tanks and container must be inertized. This inertization is operated usually at pressure conditions close to the ambient pressure, so that the containers are often exposed only to small pressure loads. So the pressure regulators for inerting applications require large diaphragms, because the closing or opening forces for the Regulators must be produced by relatively low pressure.

The three most important reasons for the inerting are:- Explosion protection and possible new defining of ex-zones into less critical zones

- Product protection, particularly by exclusion of oxygen and/or air humidity

- Environmental protection, because the frequently used chemicals or the chemical process in relation to the environment to be led safe have no critical products or chemicals which can lead to damages

The inert gas is to rinse the existing gas out of the tank as best as possible. Therefore they are in particularly large, slim and long tanks and the regulator for blanketing supply gas and the back pressure regulator should stay apart as far as possible.

APPLICATIONS

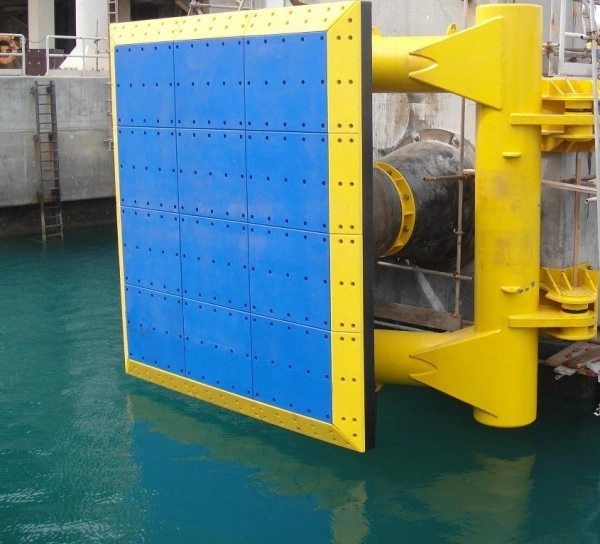

- Storage tanks

- Production tanks for chemicals, basic materials, intermediate or final products

- Chemical reactors like agitated tanks, reaction boiler, centrifuges, decanter, filter presses, distillation columns