YA series precision electronic balance

Explosion protection to

- CENELEC

- IEC

- NEC

Can be used in

This product is suitable for places with explosion-proof requirements in explosive environments such as petroleum, chemical industry, metallurgy, medicine, textile, food, bioengineering, pharmaceuticals, hazardous chemical warehouse, paint workshops, medical treat-ments, laboratories and aeroscpace engineering.

- Zone 1 and Zone 2

- Zone 21 and Zone 22

- Class I, Zone 1 and Zone 2

- Class I, Division 2, Groups A, B, C, D

Product infomation:

- Filter adjustable function

- Unit lock function

- With g, ct, oz and other units

- Horizontal mediation function

- Large screen LCD liquid crystal display

- Built-in battery, AC and DC

- RS232 factory

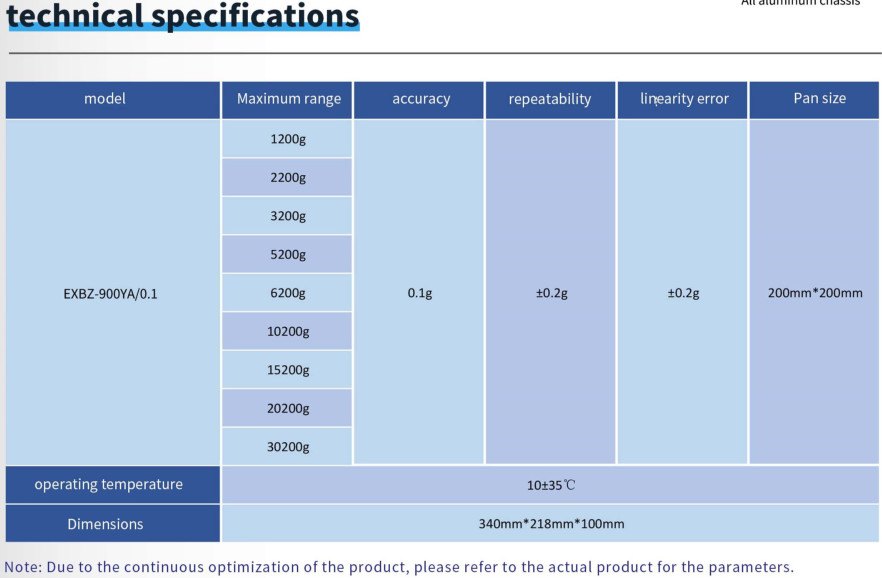

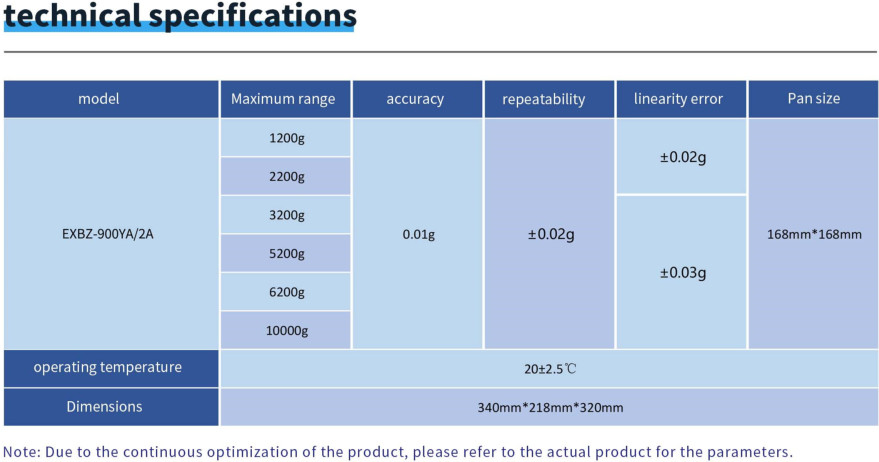

- All aluminium chassis

The application of explosion-proof scales is crucial in industries dealing with hazardous materials or operating in environments prone to fire and explosion. Some key applications include:

Chemical and pharmaceutical industries: Scales are used to accurately weigh and measure potentially explosive substances such as chemicals and flammable powders. This ensures safety for workers and prevents any accidental ignition or explosion. Oil and gas industry: In oil refineries, petroleum processing plants, and gas processing facilities, scales are used to weigh and measure volatile and flammable materials such as fuels and gases. This helps control the risk of fire and explosion in various production and testing processes. Mining and explosives production: In industries related to mining, quarrying, and explosives production, scales are used to measure and accurately mix explosive materials. This ensures the precise composition of explosives, minimizing the risk of premature detonation. Other industries Research laboratories: Scales are employed in research laboratories where hazardous materials or reactions are handled. These scales are used to accurately measure chemicals, reagents, and samples in a safe manner, protecting researchers and preventing any potential accidents. Pharmaceutical compounding: In compounding pharmacies or pharmaceutical manufacturing facilities, scales are used to measure and mix potentially explosive components for medication formulations. This ensures safety for workers and maintains the quality and consistency of products.

Overall, the primary purpose of explosion-proof scales is to prevent sparks or heat generation during weighing or handling of materials or air with explosive potential. By using these specialized scales, industries can maintain a safe working environment and minimize the risk of accidents or explosions.

Some requirements for using, maintaining, and operating explosion-proof scales in the oil and gas, paint industries to ensure safety include:

Classify hazardous areas: Understand the specific hazardous area classifications where explosion-proof scales will be used. This classification determines the level of explosion protection required for the equipment. Proper installation: Follow the manufacturer's instructions for installing the scale, ensuring it is placed in the appropriate hazardous area and connected to the proper power source. Regular checks: Conduct regular checks of the scale to ensure it is in good working condition. This includes checking for any damage, loose connections, or signs of wear and tear. If any issues are found, they should be addressed immediately. Calibration and Verification: Regularly calibrate the scale to ensure accurate measurements. Verification by a third-party calibration service may also be necessary to comply with industry standards and regulations. Preventative maintenance: Perform regular preventative maintenance as recommended by the manufacturer. This may include cleaning, lubricating, and replacing worn parts. Ensure only approved cleaning agents and tools are used in hazardous areas. Proper training: Ensure that operators and maintenance personnel are trained on how to safely use and operate the scales. They should be familiar with specific hazards associated with the equipment, emergency procedures, and proper handling techniques. Compliance with safety standards: Adhere to relevant safety standards and regulations, such as those set forth by regulatory agencies like OSHA (Occupational Safety and Health Administration) or ATEX (Explosive Atmospheres). Avoid overloading: Never exceed the maximum capacity of the scale. Overloading can lead to inaccurate measurements, equipment damage, and potential safety hazards. Avoid spark generation: Implement preventive measures to avoid generating sparks near explosion-proof scales. This includes avoiding friction, impacts, or contact between the scale and other objects that could cause sparks. Report issues: If any problems or malfunctions with the scale are observed, report them immediately to the appropriate personnel, such as maintenance or safety departments, and follow necessary procedures for repair or replacement.

By adhering to these requirements, users can ensure that explosion-proof scales operate safely and reliably while minimizing the risk of accidents or explosions in hazardous environments.