The 1st recorded dust explosion in 1785 took place at Giacomelli’s Bakery Warehouse, an Italian flour mill, when flour dust came in contact with a mounted lamp, which injured two workers. A local man named Count Morozzo examined the results of the explosion, and wrote a report giving the probable cause of the explosion as the dry flour dust. What is dust explosion? How dust explosion occur? What are materials that can be a combustible dust hazard? How to reduce risks of dust explosion? The answers for 4 above questions can be seen in as the followings.

The 1st recorded dust explosion in 1785 took place at Giacomelli’s Bakery Warehouse, an Italian flour mill, when flour dust came in contact with a mounted lamp, which injured two workers. A local man named Count Morozzo examined the results of the explosion, and wrote a report giving the probable cause of the explosion as the dry flour dust. What is dust explosion? How dust explosion occur? What are materials that can be a combustible dust hazard? How to reduce risks of dust explosion? The answers for 4 above questions can be seen in as the followings.

1. What is dust explosion?

A dust explosion is the rapid

combustion of fine combustible particles suspended in the

air within a confined space causing a powerful pressure wave to form. It can be disastrous and lead to multiple personnel deaths, injuries, and destruction of entire facilities.

2. How Dust Explosions Occur?

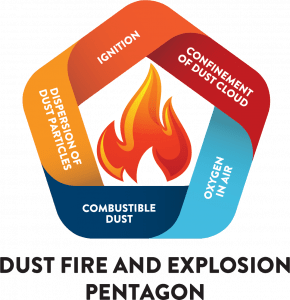

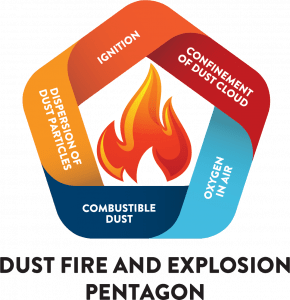

Explosion pentagon includes oxygen, heat, fuel (combustible dust), sufficient concentration of fine particles and confined space. If one element of the pentagon is missing, an explosion cannot occur.

An initial (primary) explosion in processing equipment or in an area where fugitive dust has accumulated may dislodge more dispersed dust into the air, or damage a containment system (such as a duct, vessel, or collector). As a result, if ignited, the additional dust dispersed into the air may cause one or more secondary explosions. These can be far more destructive than a primary explosion due to the increased quantity and concentration of dispersed combustible dust. Many deaths in past incidents, as well as other damage, have been caused by secondary explosions.

3. What are materials that can be a combustible dust hazard?

Many materials can be combustible, such as:

- Agricultural products: powdered milk, cornstarch, sugar, flour, rice, etc.

- Metals such as aluminium, bronze, magnesium, zinc, etc.

- Chemical dusts such as coal, sulphur, etc.

- Pharmaceuticals;

- Pesticides;

- Rubber;

- Wood;

- Textiles;

- Plastics;

4. Prevention and mitigation measures

To identify factors that may contribute to an explosion, OSHA recommends a thorough hazard assessment of:

- All materials handled;

- All operations conducted, including by-products;

- All spaces (including hidden ones); and

- All potential ignition sources.

To control dust, some recommendations can be as following:

- Implement a hazardous dust inspection, testing, housekeeping, and control program;

- Use proper dust collection systems and filters;

- Minimize the escape of dust from process equipment or ventilation systems;

- Use surfaces that minimize dust accumulation and facilitate cleaning;

- Provide access to all hidden areas to permit inspection;

- Inspect for dust residues in open and hidden areas at regular intervals;

- If ignition sources are present, use cleaning methods that do not generate dust clouds; • Use only vacuum cleaners approved for dust collection; and

- Locate relief valves away from dust deposits.

To control ignition sources:

Use appropriate electrical equipment and wiring methods;

- Control static electricity, including bonding of equipment to ground;

- Control smoking, open flames, and sparks;

- Control mechanical sparks and friction;

- Use separator devices to remove foreign materials capable of igniting combustibles from process materials;

- Separate heated surfaces from dusts;

- Separate heating systems from dusts;

- Select and use industrial trucks properly;

- Use cartridge-activated tools properly; and

- Use an equipment preventive maintenance program

To mitigate damage and fatality/injury:

Separation of the hazard (isolate with distance);

- Segregation of the hazard (isolate with a barrier);

- Deflagration isolation/venting;

- Pressure relief venting for equipment;

- Direct vents away from work areas;

- Specialized fire suppression systems;

- Explosion protection systems;

The 1st recorded dust explosion in 1785 took place at Giacomelli’s Bakery Warehouse, an Italian flour mill, when flour dust came in contact with a mounted lamp, which injured two workers. A local man named Count Morozzo examined the results of the explosion, and wrote a report giving the probable cause of the explosion as the dry flour dust. What is dust explosion? How dust explosion occur? What are materials that can be a combustible dust hazard? How to reduce risks of dust explosion? The answers for 4 above questions can be seen in as the followings.

The 1st recorded dust explosion in 1785 took place at Giacomelli’s Bakery Warehouse, an Italian flour mill, when flour dust came in contact with a mounted lamp, which injured two workers. A local man named Count Morozzo examined the results of the explosion, and wrote a report giving the probable cause of the explosion as the dry flour dust. What is dust explosion? How dust explosion occur? What are materials that can be a combustible dust hazard? How to reduce risks of dust explosion? The answers for 4 above questions can be seen in as the followings.

Explosion pentagon includes oxygen, heat, fuel (combustible dust), sufficient concentration of fine particles and confined space. If one element of the pentagon is missing, an explosion cannot occur.

An initial (primary) explosion in processing equipment or in an area where fugitive dust has accumulated may dislodge more dispersed dust into the air, or damage a containment system (such as a duct, vessel, or collector). As a result, if ignited, the additional dust dispersed into the air may cause one or more secondary explosions. These can be far more destructive than a primary explosion due to the increased quantity and concentration of dispersed combustible dust. Many deaths in past incidents, as well as other damage, have been caused by secondary explosions.

Explosion pentagon includes oxygen, heat, fuel (combustible dust), sufficient concentration of fine particles and confined space. If one element of the pentagon is missing, an explosion cannot occur.

An initial (primary) explosion in processing equipment or in an area where fugitive dust has accumulated may dislodge more dispersed dust into the air, or damage a containment system (such as a duct, vessel, or collector). As a result, if ignited, the additional dust dispersed into the air may cause one or more secondary explosions. These can be far more destructive than a primary explosion due to the increased quantity and concentration of dispersed combustible dust. Many deaths in past incidents, as well as other damage, have been caused by secondary explosions.